Victoria’s Supply Chain 2026: Imports, Lead Times and Pricing Risk for Construction and Manufacturing Inputs

This article is part of Tenfold’s Victoria’s Economy 2026 series for owners in construction, trades and manufacturing. Earlier instalments explored labour, credit conditions, business confidence and infrastructure spending. This article turns to a topic that quietly shapes margins, scheduling and project delivery: supply chains. After several years of volatility, 2026 brings something many Victorian SMEs haven’t felt in a long time: stability.

As a business coach working with Victorian tradies, builders and manufacturers, I see how supply chain conditions directly influence profitability. When lead times blow out, jobs stall. When pricing jumps unexpectedly, margins shrink. When materials arrive late or inconsistently, productivity drops. But in 2026, the story is shifting. Supply chains are becoming more predictable, imports are flowing more smoothly, and local manufacturing is stepping into new opportunities. This article explains what’s changed, where the opportunities are, and how owners can use this stability to strengthen margins and plan with confidence.

Supply Chains Are Stable, and That Creates Opportunity

After years of disruption, Victoria’s supply chain environment in 2026 is more predictable than at any point since 2019. Global freight costs have stabilised, shipping schedules are more reliable, and key materials (from steel and timber to electrical components and HVAC equipment) are flowing more consistently. Local manufacturers have also expanded capacity, offering alternatives to previously hard-to-source imports.

For construction and manufacturing businesses, this stability creates opportunity. Predictable lead times support better scheduling. Stable pricing supports more accurate quoting. And improved local supply options reduce risk and strengthen relationships. The message is positive: supply chains are no longer a threat to margins, they’re becoming a strategic advantage for well‑organised SMEs.

Imports: More Predictable, Less Volatile

Global shipping schedules have stabilised

After years of delays, port congestion and unpredictable transit times, global shipping has returned to a more reliable rhythm. This means imported materials, from fixtures and fittings to machinery components, are arriving more consistently. For Victorian SMEs, this reduces the need for excessive buffer stock and allows for more accurate project planning.

Freight costs have normalised

Shipping costs have settled well below their 2021-2022 peaks. While they remain higher than pre‑pandemic levels, the volatility has eased. This stability helps businesses quote with more confidence, knowing that freight surcharges are less likely to erode margins unexpectedly.

Key materials are flowing more smoothly

Electrical components, HVAC units, plumbing fixtures, steel products and specialised machinery parts are all more readily available. This reduces the risk of project delays and allows businesses to take on work with clearer expectations around delivery timelines.

Importers are offering more reliable forecasting

Suppliers are providing better visibility on stock levels, shipment schedules and expected arrival dates. This transparency helps SMEs plan purchasing more strategically and reduces the need for last‑minute substitutions.

Local Manufacturing: A Growing Competitive Advantage

Increased capacity in Victorian fabrication and machining

Local manufacturers have expanded capacity in response to global disruptions. This includes metal fabrication, machining, joinery, plastics, electrical assemblies and custom components. For SMEs, this means more reliable lead times and the ability to source specialised parts without relying on overseas suppliers.

Shorter lead times for custom work

Local suppliers can often deliver custom components faster than imports, especially for small‑to‑medium batch sizes. This supports faster project turnaround and reduces downtime in manufacturing environments.

Improved quality control and communication

Working with local suppliers enables clearer communication, easier quality checks, and faster issue resolution. This reduces rework and strengthens relationships that support long‑term reliability.

Growing preference for local sourcing

Many Victorian businesses (including government agencies) are prioritising local suppliers to improve reliability and reduce risk. SMEs that build strong relationships with local manufacturers are benefiting from this shift.

Lead Times: Predictable and Easier to Manage

Shorter and more consistent delivery windows

Lead times for many construction and manufacturing inputs have shortened compared to the volatility of recent years. This includes steel, timber, electrical components, HVAC equipment, plumbing fixtures and commercial building materials. Predictability enables businesses to schedule with greater confidence and reduce downtime.

Better alignment between suppliers and contractors

Suppliers are improving communication around stock availability, delivery windows and potential delays. This helps contractors plan site sequencing more effectively and reduces the risk of idle labour.

Reduced need for over‑ordering or stockpiling

With more reliable lead times, businesses can reduce excess inventory and free up working capital. This is particularly valuable in a high‑interest environment where holding costs matter more.

Improved coordination for large or staged projects

For builders and manufacturers working on multi‑stage projects, predictable lead times support smoother sequencing and reduce the risk of bottlenecks.

Pricing: Stability Supports Stronger Margins

Material prices have stabilised across key categories

Steel, timber, copper, aluminium, electrical components and HVAC equipment have all reached a more stable pricing range. While prices remain higher than pre‑2020 levels, the rapid month‑to‑month fluctuations have eased. This stability supports more accurate quoting and reduces the risk of margin erosion.

Suppliers are offering clearer forward pricing

Many suppliers now provide forward pricing windows, allowing businesses to lock in costs for upcoming projects. This is particularly valuable for fixed‑price contracts where cost certainty is essential.

Reduced volatility improves client confidence

Clients are more willing to proceed with projects when pricing is stable. This supports stronger demand in both construction and manufacturing, especially for commercial and industrial work.

Opportunities to negotiate better terms

With supply chains stabilising, some suppliers are more open to negotiating pricing, delivery schedules or payment terms, especially for businesses that order consistently or maintain strong relationships.

How Supply Chain Stability Supports Growth

Better scheduling and fewer delays

Predictable lead times allow businesses to plan labour, equipment and subcontractors more effectively. This reduces downtime, improves productivity and supports more reliable project delivery.

More accurate quoting and stronger margins

Stable pricing allows businesses to quote with confidence. When material costs are predictable, margins are easier to protect – especially on fixed‑price work.

Reduced cashflow pressure

With less need to stockpile materials or place large upfront orders, businesses can preserve working capital. This is particularly valuable in a tight credit environment.

Stronger client relationships

When businesses deliver on time and on budget, clients trust them more. Supply chain stability supports this reliability and strengthens long‑term relationships.

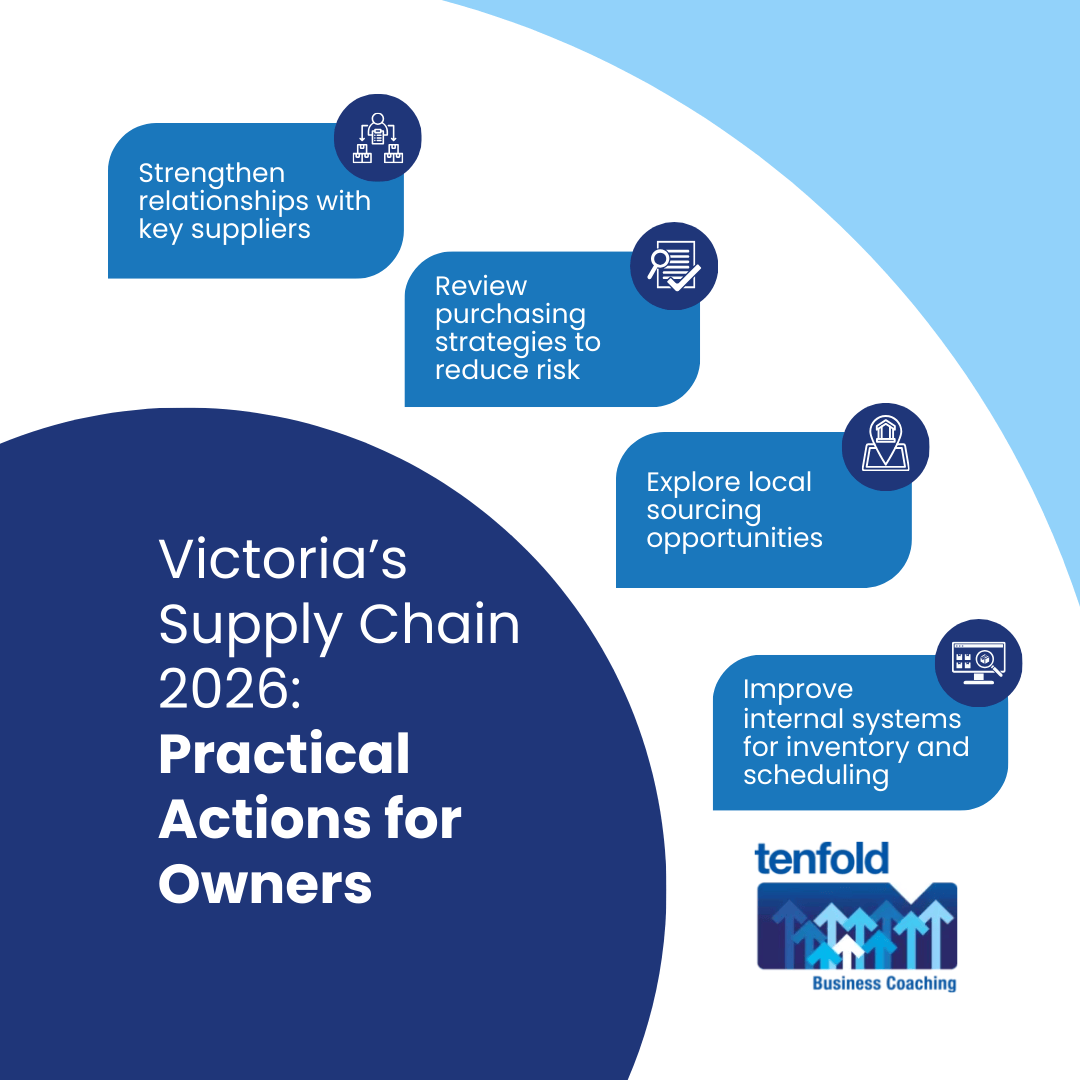

Practical Actions for Owners in 2026

Strengthen relationships with key suppliers

Reliable suppliers are strategic partners. Businesses that communicate clearly, order consistently and pay on time often receive priority access to stock, better pricing and more accurate forecasting.

Review purchasing strategies to reduce risk

With supply chains stabilising, businesses can shift from reactive purchasing to planned procurement. This includes forecasting demand, aligning orders with project schedules and negotiating forward pricing where possible.

Explore local sourcing opportunities

Local manufacturers offer faster lead times, better communication and reduced risk. Businesses that diversify their supply base (combining imports with local suppliers) are more resilient and more competitive.

Improve internal systems for inventory and scheduling

Stronger internal processes help businesses take full advantage of supply chain stability. This includes job management systems, inventory tracking, purchasing workflows and clearer communication between office and site teams.

Tenfold Insights: What We’re Seeing Across Victoria

Across the businesses we coach, the strongest performers are those who treat supply chain stability as a strategic advantage. They’re improving scheduling, tightening purchasing processes, strengthening supplier relationships and using predictable pricing to protect margins. They’re also exploring local sourcing options that reduce risk and support faster turnaround.

We’re also seeing that businesses with strong internal systems are benefiting the most. When documentation, communication, and forecasting are clear, supply chain stability translates into better margins, smoother deliveries, and stronger client relationships.

Supply Chain Stability Creates Opportunity for Strong Operators

Victoria’s supply chain environment in 2026 is more stable, predictable and opportunity‑rich than it has been in years. Imports are flowing smoothly, local manufacturing is stronger, lead times are more consistent, and pricing is more stable. For construction and manufacturing businesses, this creates a foundation for confident planning, stronger margins and more reliable project delivery.

As a business coach working with Victorian trades, builders and manufacturers for over 20 years, I’ve seen how supply chain stability can transform profitability. If you want support strengthening your purchasing, scheduling and operational systems, learn more about how Tenfold’s business coaches work one‑on‑one with owners through our business coaching services.