Victoria’s Labour Market 2026: Wage Pressure, Skills Shortages and Migration Impacts for Trades, Construction and Manufacturing

This article is part of Tenfold’s Victoria’s Economy 2026 series for owners in construction, trades and manufacturing. In the opening article, I outlined the broader economic backdrop shaping demand in Victoria: moderate growth, uneven sector performance and ongoing household pressure. This instalment focuses on the labour market (availability, wages and migration) and what these forces mean for your pricing, capacity and workforce planning as you prepare for 2026.

As a business coach working closely with Victorian trades, builders and manufacturers, I see the labour market’s impact on margins more clearly than any other factor. Labour is the biggest cost line for most operators, and the hardest to scale. This article breaks down the current conditions (as of late 2025), the likely 2026 trajectory, and the practical steps I advise owners to take to stay competitive and profitable.

Victoria’s Labour Market Outlook for 2026

Victoria’s labour market remains tight heading into 2026, even as conditions ease slightly from the extreme shortages of 2021-2023. ABS data shows unemployment stabilising at low levels, participation remaining high, and job vacancies still elevated across construction, trades and manufacturing. Wage growth has moderated but remains above long-term averages, driven by competition for skilled labour and ongoing enterprise agreement increases. Migration has helped at the entry-level end of the market, but it has not solved shortages in licensed trades, technical roles or experienced supervisors.

For business owners, this environment demands disciplined workforce planning, structured onboarding, and pricing models that reflect true labour costs. At Tenfold Business Coaching, we’re helping clients build resilient labour strategies that protect margins and reduce dependency on hard-to-find skills.

Victoria’s Labour Market: Still Tight, But Slowly Easing

The Victorian labour market has shifted from a crisis-tight situation to a structurally tight one. Even with some easing, the fundamentals remain unchanged. Skilled labour remains difficult to secure, and competition for experienced workers remains intense.

Unemployment is currently in the low four percent range, and participation rates are high. This indicates that most people who want to work already have jobs. Job vacancies across sectors such as construction, engineering, maintenance, and manufacturing remain well above pre-2020 levels. These persistent shortages are maintaining pressure on wages and extending recruitment timelines.

For owners and operators, the practical implication is clear: labour availability will continue to constrain growth. Many hope that conditions will return to normal, but the reality is that the labour market has reset. The businesses that perform best in 2026 will be those that plan for labour scarcity rather than waiting for it to ease.

Wage Pressure: Elevated and Sticky

Wage growth has come off its peak but remains stubbornly high. In construction and manufacturing, wages are increasing faster than the national average, and enterprise agreements are locking in annual rises of 3.5-5%. Skilled workers (particularly licensed trades, supervisors, estimators and project managers) are commanding premium rates because demand for their capabilities continues to exceed supply.

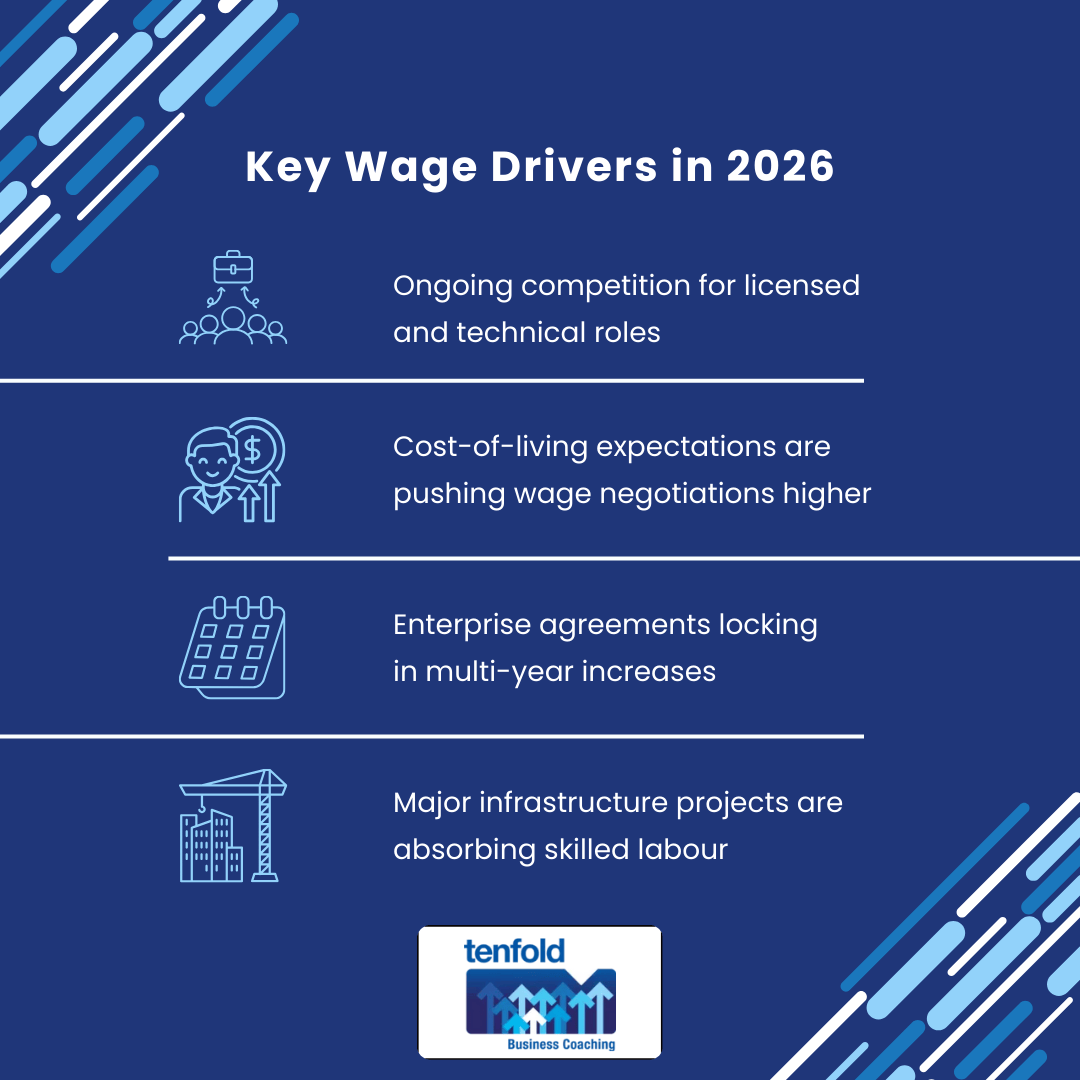

Key Wage Drivers in 2026

- Ongoing competition for licensed and technical roles

- Cost-of-living expectations are pushing wage negotiations higher

- Enterprise agreements locking in multi-year increases

- Major infrastructure projects are absorbing skilled labour

These wage pressures aren’t temporary. They’re being driven by structural factors that won’t unwind quickly. For business owners, this means labour recovery rates must be updated regularly, not just once every few years. Underpricing labour is one of the fastest ways to erode margins, especially for fixed-fee work where wage increases flow straight through to the bottom line.

Skills Shortages: The Structural Constraint

Skills shortages remain the biggest labour challenge for Victorian SMEs. The National Skills Commission continues to list electricians, plumbers, refrigeration mechanics, welders, fabricators, carpenters and civil plant operators as occupations in persistent shortage. These shortages are not cyclical; they’re structural. Training pipelines are slow, apprenticeship completion rates remain low, and experienced workers are retiring faster than new entrants are arriving.

Roles in persistent shortage

- Electricians and electrical supervisors

- Plumbers and gasfitters

- Refrigeration and HVAC technicians

- Welders, fabricators and machinists

- Carpenters and civil plant operators

For owners, this means recruitment will remain slow and competitive. It also means that relying on “finding the right people” is no longer a viable strategy. The strongest operators we coach are reducing their dependency on scarce skills by standardising assemblies, improving job sequencing, investing in supervision, and tightening scopes to reduce rework. These operational improvements often deliver more capacity than hiring an extra technician.

Migration: Helpful, But Not a Silver Bullet

Migration has increased significantly since borders reopened, and Victoria continues to attract a large share of new arrivals. This influx has helped ease pressure across industries such as labouring, warehousing, logistics, and general manufacturing. The additional migrants have helped address labour shortages in these sectors, supporting economic activity and operational efficiency.

However, migration has not meaningfully improved availability in licensed trades or technical roles. Overseas qualifications often require bridging programs, and licensing pathways are often slow to process. Furthermore, experience levels among migrants vary widely, which can impact their productivity and suitability for certain roles. English proficiency is another critical factor; limited language skills can affect safety, productivity, and client communication.

For business owners and industry leaders, the key takeaway is that migration will assist primarily with entry-level and semi-skilled labour. It does not provide a comprehensive solution to the shortages of roles critical to productivity and supervision. Therefore, workforce planning for 2026 must acknowledge this reality. Strategies should focus on developing local talent and strengthening training pipelines for skilled trades and technical roles to ensure a resilient, capable workforce in the years ahead.

Labour Productivity: The Hidden Margin Lever

In a tight labour market, productivity becomes the most important margin driver. Across the trades and manufacturing businesses we coach, we regularly see productivity gaps of 20-40% between average and high-performing teams.

These gaps rarely come down to individual effort. They are usually caused by operational issues such as poor job sequencing, unclear scopes, missing materials, inefficient supervision, excessive travel time, or rework.

Improving productivity does not require dramatic changes. Strengthening pre-start processes, tightening supervision ratios, reducing travel inefficiencies, and standardising work can unlock significant capacity.

Many of these improvements result in a greater increase in output compared to hiring additional staff, and notably, they accomplish this without the need to increase wages.

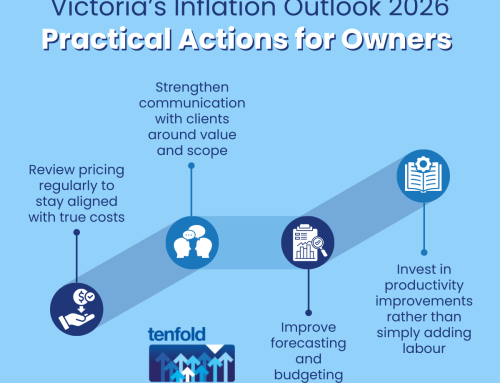

Practical Actions for Owners in 2026

To stay competitive in a tight labour market, owners should focus on a few high-impact actions:

Review Labour Recovery Rates Annually

On an annual basis, ensure that your organisation’s pricing accurately reflects the true wage costs, overhead expenses, and supervision requirements involved in each project or service. This regular review helps maintain financial accuracy, competitiveness, and profitability by adjusting for changes in labour costs and operational overheads.

Strengthen Onboarding and Supervision

Enhance the onboarding and supervision processes, particularly for apprentices and new hires, to ensure they receive comprehensive training and guidance. This approach aims to reduce the need for rework, accelerate their integration into the team, and ultimately improve overall productivity and performance.

Tighten Job Sequencing and Pre-Start Processes

To improve the efficiency and effectiveness of project execution, it is essential to tighten the job sequencing and pre-start processes. When these processes are well-structured and meticulously planned, teams arrive on site with clear scopes of work, complete materials, and minimal downtime, which ultimately leads to smoother operations and timely project completion.

These steps consistently deliver better margins and more predictable output across the businesses we coach.

Conclusion: Build a Workforce Strategy That Protects Your Margins

Victoria’s labour market in 2026 will remain tight, competitive and costly. Skilled shortages won’t disappear, wage pressure will continue, and migration will help only at the margins. The businesses that thrive will be the ones that plan proactively, price accurately and build systems that reduce dependency on scarce skills.

As a business coach working with Victorian trades, builders and manufacturers for over 20 years, I’ve seen how disciplined workforce planning transforms profitability. If you want support building a stronger, more resilient labour strategy, learn more about how Tenfold’s business coaches work one-on-one with owners through our business coaching services.

Table of Contents

- Victoria’s Labour Market Outlook for 2026

- Victoria’s Labour Market: Still Tight, But Slowly Easing

- Wage Pressure: Elevated and Sticky

- Skills Shortages: The Structural Constraint

- Migration: Helpful, But Not a Silver Bullet

- Labour Productivity: The Hidden Margin Lever

- Practical Actions for Owners in 2026

- Conclusion: Build a Workforce Strategy That Protects Your Margins